Revolutionizing freeze dried Marshmallows Production with Weber WeDry Vacuum Freeze-Drying

In the ever-evolving world of confectionery, vacuum freeze drying has emerged as a game-changing technology, revolutionizing the production of freeze dried marshmallow treats.

The Magic of Freeze Dried Marshmallows

This innovative process, perfected by Weber Vacuum Group, is transforming how we enjoy these fluffy freeze dried marshmallows while opening up new possibilities for manufacturers and consumers alike. These lightweight, crunchy versions of the classic treat offer a unique sensory experience that's captivating consumers worldwide.

The freeze-drying process intensifies the marshmallow's sweetness, creating a more concentrated flavor that bursts in your mouth. This enhanced taste profile makes freeze-dried marshmallows an irresistible snack

Gone is the familiar chewiness of traditional marshmallows. In its place, you'll find a delightfully crisp texture that melts on the tongue, offering a satisfying crunch followed by a moment of sweet dissolution. This textural contrast adds an exciting dimension to desserts, hot beverages, and even savory dishes.

In a photo, you can see a difference in volume between Vacuum Freeze-Dried marshmallow and a regular one. There is a huge gain in volume after Vacuum Freeze-Drying.

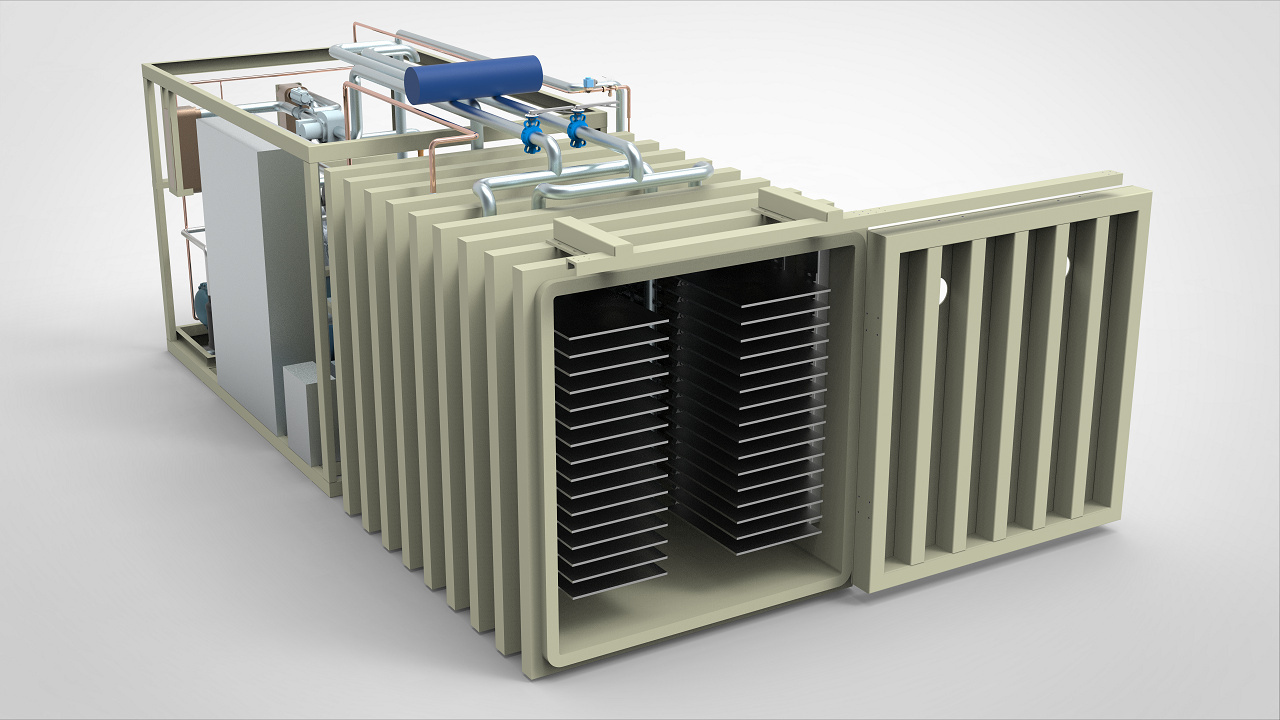

Optimized Vacuum Freeze-Drying technlogoy

Weber's vacuum freeze-dryers utilize sophisticated temperature management systems, crucial for preserving the delicate structure of marshmallows. This precision ensures that the product freezes evenly and sublimes efficiently, resulting in a consistently high-quality end product.

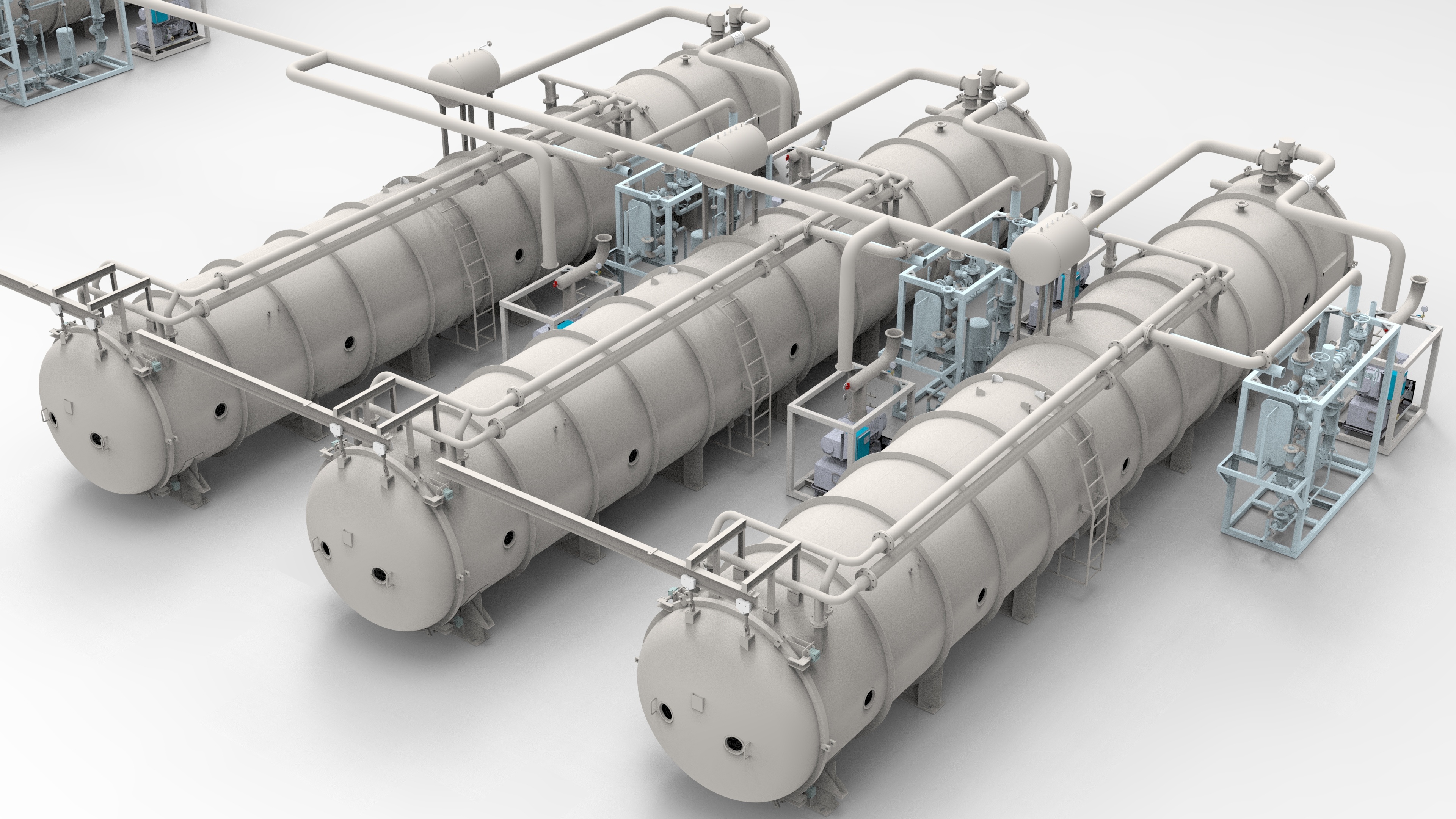

Our vacuum systems create the ideal low-pressure environment for sublimation, allowing ice to transform directly into vapor without passing through the liquid phase. This gentle process preserves the marshmallow's structure and nutritional content, resulting in a product that's as close to the original as possible, minus the moisture.

Benefits for Manufacturers and Consumers

Adopting Weber's vacuum freeze-drying solutions for marshmallow production offers numerous advantages:

- Extended Shelf Life

Freeze-dried marshmallows can last many years when properly packaged, reducing waste and expanding market reach for manufacturers. - Lightweight and Portable

The significant reduction in weight makes freeze-dried marshmallows ideal for inclusion in trail mixes, camping supplies, and space-efficient packaging. - Versatility in Applications

From gourmet hot chocolate toppings to innovative baking ingredients, freeze-dried marshmallows open up new culinary possibilities for both home cooks and professional chefs.

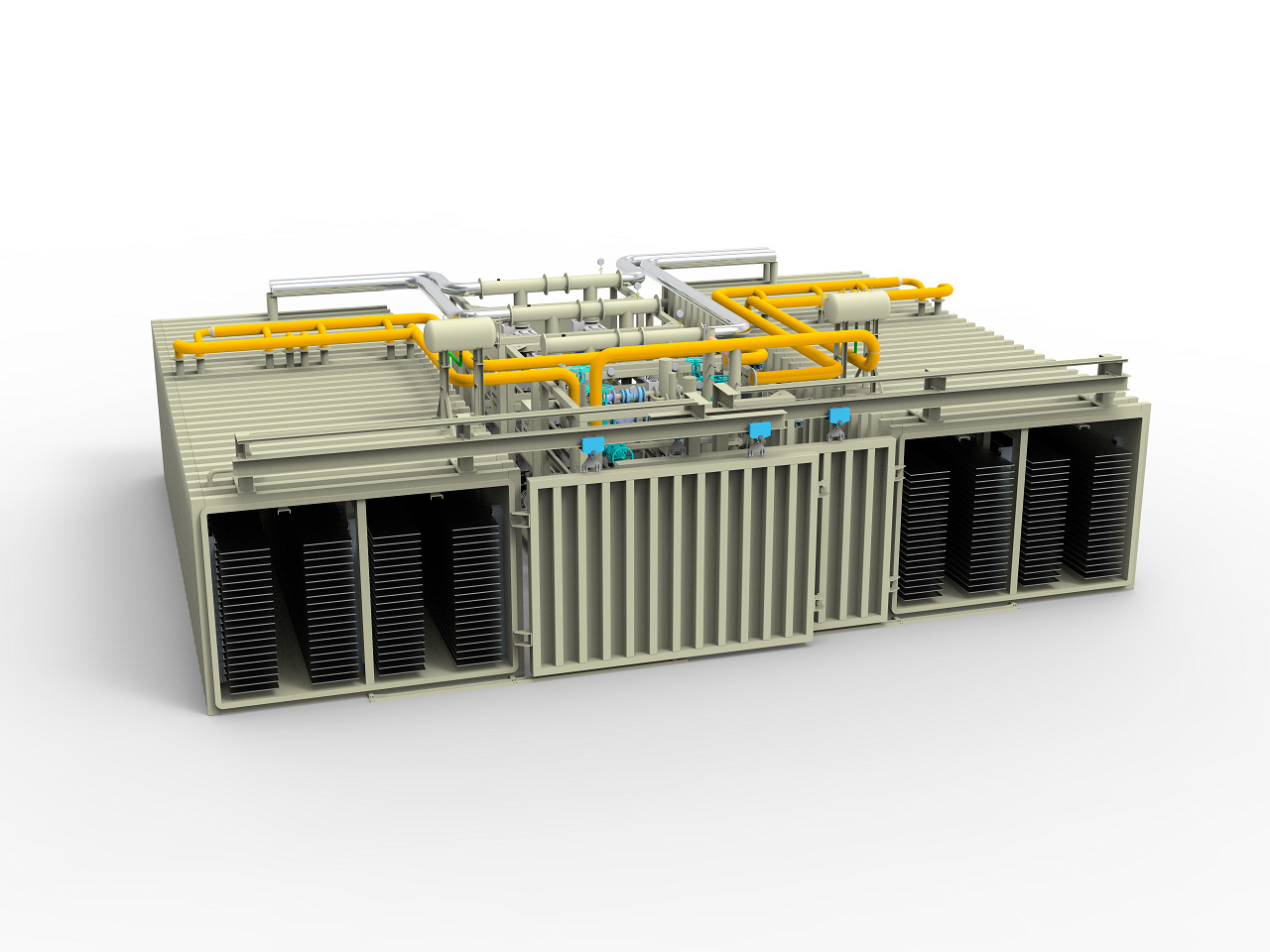

Going forward with Weber WeDry Range

As consumer demand for unique, long-lasting, and versatile confectionery products continues to grow, Weber Vacuum Solutions stands ready to support manufacturers in meeting this need. Our freeze-drying technology not only enhances the marshmallow experience but also provides a competitive edge in a rapidly evolving market. By choosing Weber's vacuum freeze-drying solutions, marshmallow producers can:

- Diversify their product lines

- Tap into new market segments

- Reduce transportation and storage costs

- Offer consumers a novel and exciting product

In conclusion, vacuum freeze drying is more than just a preservation method; it's a gateway to innovation in the confectionery industry. With Weber's cutting-edge technology, marshmallow manufacturers can elevate their products, delight consumers, and stay ahead in a competitive market.

Embrace the future of sweet treats with Weber Vacuum Solutions – where tradition meets innovation in every crispy, flavorful bite.

Weber Vacuum Freeze Drying brochure

Click on Download button to get our latest Weber Vacuum Freeze Drying brochure